This year’s ARC Industry Forum Americas was full of engaging conversations and knowledge sharing as we as an industry continue our pursuit of industrial transformation.

If you missed Cognite, we had sessions from Celanese, B.Braun, and PGS, each sharing how they use Cognite Data Fusion® to be the industrial data foundation to improve their operations.

Listening to end-user presentations, hearing their challenges in conversations, and seeing demonstrations across a variety of industrial vendors, the following three themes emerged:

- Openness and interoperability of solutions

- “Bring intelligence to operators like a pilot”

- Begin projects with scale in mind

Openness and interoperability of solutions

Many enterprises have a portfolio of brown-field facilities with diverse systems across historians, MES, asset performance management (APM) solutions, etc. While some sites make decisions independently, acquired sites usually come with a new solution portfolio that must be considered. In both cases, the result is a heterogeneous environment with limited standardization. Here, the need for vendors to provide more openness and interoperability into solutions is critical to leveraging the value of existing solutions and providing an easier way to move information across the organization.

For Cognite, we built everything in our product portfolio on fully documented public APIs (you can access our API here), and it is all designed to be a part of our customer’s enterprise architecture.

Further on openness and interoperability, we are graph-based, with our unique data contextualization capabilities sometimes referred to as “ETL to populate the graph” — with the resulting data models also possible to export out of Cognite Data Fusion®, of course (along with any and all other data), should this be desired.

Translating this tech into customer value, especially regarding our work in the process industries more broadly — you can find a case study of Celanese online (How Celanese uses Cognite Data Fusion to power its “Digital Plants of the Future”).

“Bring intelligence to operators like a pilot”

This was a powerful quote from P&G onstage that best captured the need to put people at the center of transformation. Operators and engineers deserve the same access to data as we have in our consumer world. During a session on APM with Braskem, one of the goals of their APM program is “to give time back to our engineers.” Pfizer’s digital team has a UX design team that works with the future end users of the hundreds of solutions their digital team has deployed. Technology must become easy to adopt and make day-to-day decision-making faster and more accurate.

At Cognite, we are working to support end users to build a data foundation that enables users out in the field or working remotely to google their data. Information must be easier to find and apply to increase the speed and scale teams can make data-driven decisions.

Begin projects with scale in mind

As many have experienced the pains of pilot purgatory and the inability to scale successful pilot solutions, there is a refined focus on selecting partners that can enable scale. Attendees discussed two elements of scaling in multiple sessions and on the exhibit floor. One element of scale is performance and the ability to handle the volume, speed, and many data types of industrial data. The other element of scale is a key focus of CESMII regarding how we must lower the cost and shorten the time of digital deployments to create more opportunities for small- and medium-sized manufacturers to also benefit from digital.

Cognite’s cloud-native architecture enables performance at scale. For a little bit on the cloud side of time series data, Cognite has a highly optimized time series database (TSDB) embedded inside the Cognite Data Fusion platform). Below are some high-level specs on our TSDB, with the full article titled Anatomy of a highly optimized time series database (TSDB) for real-time industrial applicationsavailable.

As of this writing, the largest Cognite Data Fusion® Time series cluster stores around 15 trillion data points and can consistently handle 40 million data points per second ingested and 200 million data points per second read. We expect to be able to scale considerably higher than this.

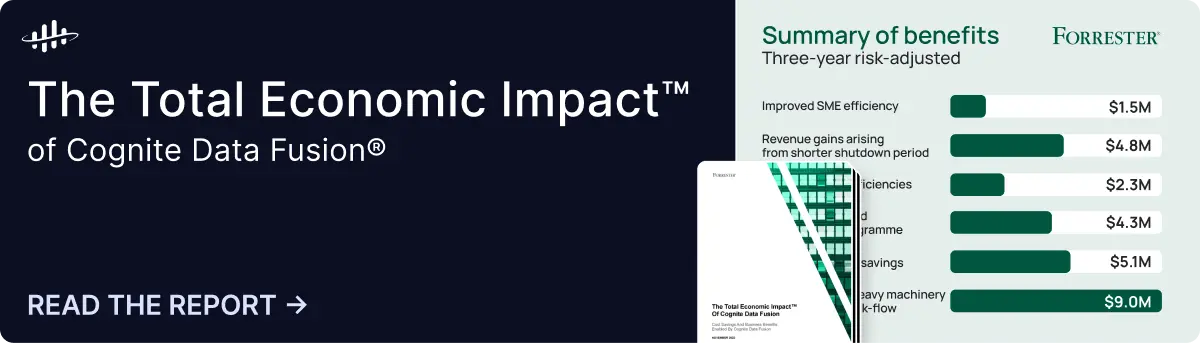

We can also see the challenge of scaling to small- and medium-sized manufacturers within large enterprises where success is often limited to one lighthouse site with very few active business users. Cognite has been helping manufacturers scale solutions across their organization and has been able to deliver a 400% ROI, according to a recent Total Economic Impact report from Forrester.

To illustrate the power of scaling, for one chemical customer working with Cognite, we onboarded one unit at one site in three months. Over the next seven months, we onboarded eight additional units, reducing the deployment time from three months per unit to less than one month per unit. Over the next twelve months, we plan to scale this to an additional 30+ sites. We are delivering business impact with a plan for scale.