This article was originally published in Hart Energy.

Industrial Dataops is the future of industrial data management in the oil and gas industry and necessary to succeed in any organization’s digital transformation strategy. Extending the lifetime and improving the reliability of assets is one of the main priorities in the oil and gas industry to make operations safer and more sustainable while remaining profitable.

Industry has a big disconnect between the estimated and realized operational value of data-driven solutions. Chasing the promise of increased uptime, reduced maintenance costs and increased productivity, most industrial companies have developed at least a handful of proofs of concept. However, while many of those pilots are considered successful, only a few make it into production. Even fewer end up scaling and providing substantive return on investment (ROI).

Industrial data operations (DataOps) can enable companies in asset-heavy industries to operationalize and scale their digital programs to unlock ROI at scale. This emerging software category, which analysts at Gartner describe as a “collaborative data management practice focused on improving the communication, integration and automation of data flows between data managers and data consumers across an organization,” is shifting the focus from how industrial data is retained and controlled to how the data is used and accessed.

Industrial challenges call for Industrial DataOps

Take, for example, extending the lifetime and improving the reliability of assets—one of the main priorities in the oil and gas industry to make operations safer and more sustainable while remaining profitable. As part of that work, many operators are expanding their remote work capabilities (especially in light of the COVID-19 pandemic), which requires new digital technology integrations and upskilling of existing employees.

OMV, an Austrian integrated oil and gas producer, is one such operator. When the company recently sketched out a plan for a new remote asset integrity operations framework, it outlined a number of priorities:

- Reduce the costs of unplanned downtime. As the global cost of downtime rises, the need to maximize uptime has become imperative for OMV to stay resilient in the face of unpredictable market trends.

- Lower the cost of asset condition monitoring, inspection and maintenance planning. Better visibility of equipment condition, efficiency, and performance would enable efficient central planning, scheduling and dispatching of front-line maintenance operators.

- Cut unnecessary maintenance hours and associated costs. Inadequate and inaccessible information about asset condition necessitates costly manual inspections and more frequent maintenance trips.

- Improve procurement and business planning. Easily accessible information helps operators and procurement managers optimize spare parts management for repair and replacement.

- Ensure compliance with health, safety, security, and environmental (HSSE) regulations. Eliminating unnecessary inspection and maintenance trips offshore also reduces safety hazards.

These priorities all indicated a clear need for a more sophisticated, holistic approach to data collection, processing and visualization to aid remote inspection, collaboration, training, certification, audits and precommissioning. In other words, the project called for Industrial DataOps.

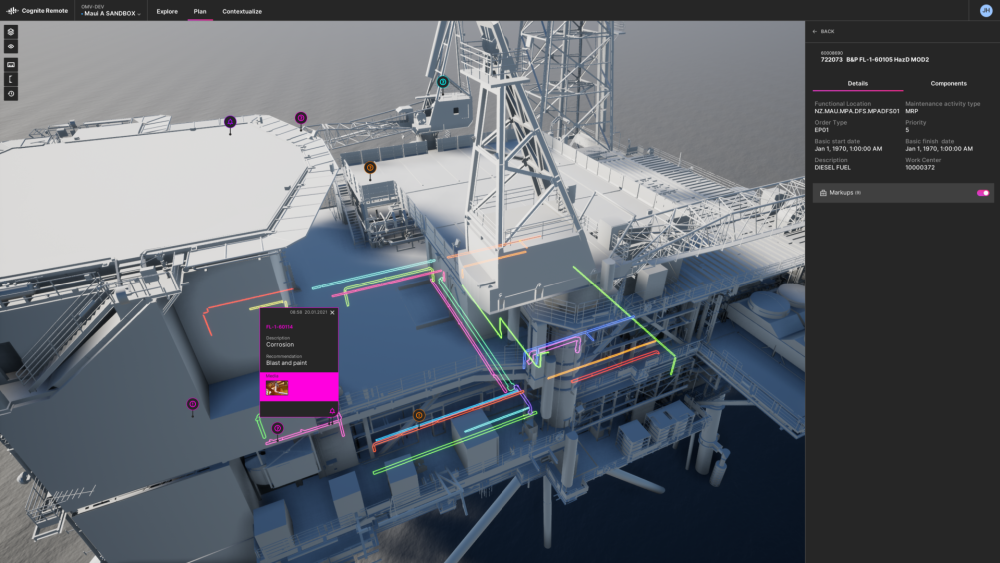

Cognite remote contextualizes siloed data.

Cognite remote contextualizes siloed data.

From disparate data to digital twin

To provide a complete, actionable understanding of the company’s physical and digital assets and processes, OMV built a dynamic, high-fidelity 3D digital twin made up of data from its various disparate systems. OMV used an Industrial DataOps platform to connect and contextualize massive amounts of information, including visual information from engineering diagrams, CAD models, 360-degree images, point cloud data, and photogrammetry models.

Via artificial intelligence (AI)-driven augmentation techniques, the digital twin was further contextualized with geotags, information about scaffolding requirements and inspection checklists, high-frequency time series from individual sensors and access to all relevant documentation.

The digital twin makes information about enterprise-wide assets and processes dependable and meaningful. And since it’s easily accessible on computers and smart devices using the same application, the information is available anywhere.

Today, OMV’s maintenance and inspection planners and operators can collaborate using the same application to streamline maintenance planning activities remotely, with no need to travel offshore. When conducting inspection, maintenance staff and process engineers receive comprehensive work packs with 3D visualizations and files. Using a tablet or mixed reality devices such as Microsoft HoloLens 2, operators in the field can view virtual elements overlaid on physical assets and work orders for operations or training needs.

OMV’s Cognite remote application in planning mode.

OMV’s Cognite remote application in planning mode.

A new era of data management

With remote asset integrity programs based on Industrial DataOps, OMV is well on its way to realizing the vision of managing assets autonomously, backed by an adaptive digital workforce. Ultimately, the company estimates that the solution will cut planning time by 25% and operating expenses by 50%, and help OMV reduce its environmental footprint.

As the digital twin provides a single entry point to all relevant inspection data, there is no need to access disparate data sources and applications. Access to contextualized data is now instantaneous.

All of OMV’s asset integrity operations can now be planned remotely, changing the way OMV’s experts work and collaborate:

- Maintenance service staff can reduce the number of trips they take offshore, significantly cutting travel and maintenance costs. When a trip offshore is required, remote, real-time operations with onshore and offshore staff connected for technical support will optimize resource use.

- Mobile devices help offshore operators access data contained in work packs, while mixed reality devices such as HoloLens 2 further improve remote technical assistance and asset vendor support, keeping all stakeholders connected whenever a need for troubleshooting arises. This is of tremendous value for certifications, precommissioning and audits.

- Digitalization and digital twins can contribute to more efficient resource use, giving OMV the information and tools the company needs to reduce its environmental footprint.

Augmented data management is ushering in a new era of asset management, where the long-anticipated collaboration between humans and machines—in particular AI—becomes a reality. This same data can be used across a number of applications and solutions including, boosting field efficiency, increasing your production potential, activating robotics ecosystems, or transforming company operations to reduce emissions.

In this new environment, the organizations that succeed will be those who can take the leap beyond traditional approaches. Democratizing data through intuitive, user-friendly applications means that more people can glean predictive and prescriptive insights and manage their operations more effectively. Even though these “citizen data scientists” may not have the same analytical or technical skills as expert data scientists, Industrial DataOps lowers the barrier for them to drive real value for the enterprise.