Key takeaways:

- MES and Industrial DataOps are distinct and important to the manufacturing landscape

- Do not underestimate the hidden costs of maintaining reliable digital solutions

- Use Industrial DataOps to own your digital future

The industrial software landscape is changing. Traditional software offerings are expanding their capabilities and blurring the lines of their original scope; ERPs suddenly want process data to support asset management modules, while historians are asking for asset data to run advanced analytics. At the same time, the amount of data generated by industrial operations is growing at an exponential rate. Research by the global market intelligence firm IDC suggests the amount will triple over the next five years.

Read in Cognite Community Hub: DataOps: A transformative new approach to data ROI →

These changes are generating confusion among manufacturers who are looking for one thing: data that delivers value and helps them remain competitive and sustainable.

At Cognite, we help organizations gain value from their data and achieve their digital initiatives with our industrial DataOps platform, Cognite Data Fusion®. When with sit down with manufacturers to talk digital transformation, one question consistently arises:

"I'm already using an MES. Why do I need an industrial DataOps Platform?"

This question indirectly acknowledges the confusion in the industrial software landscape. To answer this question fully, we need to understand the use cases that industrial DataOps enables that are not practically addressed with an MES.

Simply put, the answer has to do with data. The amount of OT data and the number of data sources are growing at a rate much faster than they can be consumed — in fact, only 30% of the data generated will be consumed and adequately utilized by 2025. Unconsumed data creates neither insights nor value for your organization.

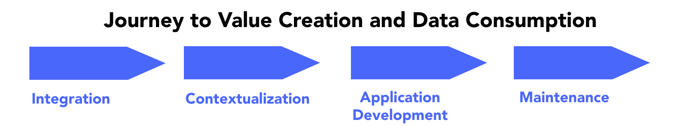

Since the first step to data consumption is integration, it might seem logical to build around the MES, which already integrates with process equipment, SCADA, ERP systems, and more. However, data integration on its own doesn’t create much value; it’s merely the first step toward developing applications that generate insights. In comparison, industrial DataOps addresses the entire value creation process to enable easier consumption of insights for your organization.

Here’s how:

| Integration |

Integration with industrial DataOps is differentiated by two metrics: openness and the ability to leverage existing integrations. Industrial DataOps supports a range of flexible data integration patterns, including open protocols like OPC UA, and also offers software development kits (SDKs) and open APIs. The goal is to minimize efforts required in this step and leverage any existing integrations — including from an MES or an Azure Data Lake — to get manufacturers to the later, more valuable stages of the data consumption process faster.

Read also: Use DataOps to deliver to both SMEs and professional data scientists →

| Contextualization |

Contextualization makes data discoverable and usable. For example, if you search your P&IDs for “Pump-202,” contextualization is the behind-the-scenes magic that fetches not just the correct document, but also real-time process data, open work orders, vibration health, and maintenance documents — all in a single location. Discoverable data reduces the time to value by speeding up application development.

Learn more: How to scale use cases with data contextualization →

Automatic contextualization is a key point of differentiation for industrial DataOps. While many other types of software offer some form of data contextualization, this is often a manual process. Industrial DataOps solutions contextualize data with machine learning (ML) services. This means building and maintaining relationships can be performed 15-20 times more efficiently. Additionally, the contextualization model created by industrial DataOps is designed to grow as more data sources are added.

A contextualized P&ID with live process data from transmitters and assets.

| Application Development |

Most Manufacturing Execution Systems rely on system integrators or third parties to develop new use cases, which can make projects take too long and cost too much. Industrial DataOps creates an environment with usable data that supports your organization’s needs to build digital expertise internally and solve use cases specific to your operations. Industrial DataOps also enables more complex analytics use cases such as physics-based machine learning (also known as hybrid AI) for production optimization, which is not an immediate need for an effective MES.

Read also: Physics and AI hybrid deliver working AI for industry →

| Maintenance |

Too often, application development itself is seen as the home stretch of the data consumption process. What’s often overlooked is the effort to maintain and ensure trust in solutions. A contextualized data model no longer built on point-to-point relationships drastically reduces the resources needed to maintain each solution and use case. Industrial DataOps also includes data quality monitoring, ensuring that data used to drive decisions is auditable and trustworthy. Analytics models built without data quality monitoring can take hours to verify, and after a few false positives, solutions may be labeled untrustworthy and eventually abandoned.

Learn more: 4 tech predictions for 2022 →

Another important point about the difference between an MES and industrial DataOps has to do with what use cases the solutions can address. An MES is designed to support the transformation of raw materials into finished products, which will be a key technology to enable smart manufacturing. Industrial DataOps, meanwhile, makes contextualized data usable to your organization for a variety of use cases across production, sustainability, asset performance, and quality. Still, some overlap exists:

When thinking about how to approach use cases like production dashboards, OEE, and reporting, manufacturers should consider their digital ambitions and desire to take ownership over their digital futures. Many are already doing so. IDC’s research suggests that 60% of organizations will have begun implementing industrial DataOps solutions by 2023. The organizations that take the necessary steps now to streamline the data consumption process will gain a competitive advantage in the future.

The amount of data generated by industrial operations will only continue to grow. Industrial DataOps offers the functionality to not just keep up, but to improve the time to value, quality, predictability, and scale of the entire operational data analytics life cycle.

About Cognite

Cognite is a global industrial AI Software-as-a-Service (SaaS) company supporting the full-scale digital transformation of heavy-asset industries around the world. Their key product, Cognite Data Fusion®, empowers companies with contextualized OT/IT data to drive industrial applications that increase safety, sustainability, and efficiency, and drive revenue.