The solution will help Aarbakke reduce tool assemblies by 60% and increase cutting tool efficiency by 10%.

Challenge

Reduce cutting tool inefficiency

Aarbakke’s computer numerical control (CNC) machines use more than 22,000 unique cutting tools to complete complex operations on sometimes rare materials.

Because of old numerical control programs, lack of operator experience, and other reasons, these tools are sometimes used in an inefficient way. Operators and production managers are only aware of a suboptimal cutting process once the part is finished.

It is also difficult to get an overview of tool usage and performance. Some tools may be in use for hundreds of minutes in a single day, while others may hardly be used at all.

Solution

Liberate data, visualize it, and use it to optimize tool usage

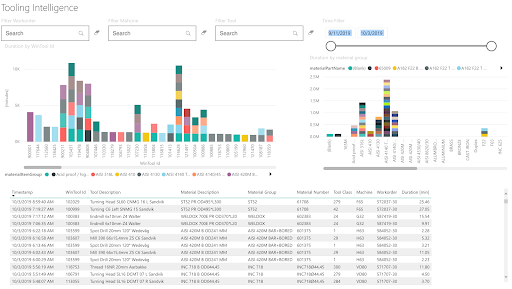

Aarbakke already had in place separate systems that tracked machine operation data and work orders—the systems just didn’t communicate with each other. Cognite and Aarbakke liberated the data from the systems and collected it all in Cognite Data Fusion®, and then visualized it in a dashboard.

The dashboard gives production managers, team leaders, and operators an overview of which tools are most frequently in use and color-codes the usage based on the material that the tool is cutting into. Aarbakke can use this information to optimize tool usage during cutting and reduce cutting time.

Impact

By analyzing historical use of tool assemblies and their performance, Aarbakke aims to reduce tool assemblies by up to 60% and boost the efficiency of the remaining tools by 10%, resulting in an estimated annual value generation of $6 million.